The Amazing 12V Brushless Motor - Everything You Need to Know.

Advantages of 12V Brushless Motor

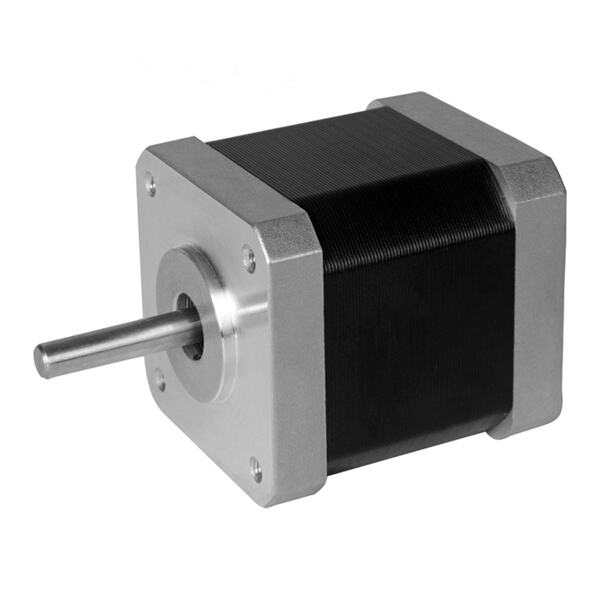

A 12V Brushless Motor can be a type for this is gaining in appeal. Many significant advantage of motor is it is effectiveness. It makes energy industries that are utilizing magnetic of technical brushes, ultimately causing less friction in addition to heat loss, making it a lot more energy efficient.

Since brushless motors generate less temperature, they have been stronger, require less maintenance, and could last longer, just like the LEISON's product called dc planetary gear motor. Also, these are typically quieter and produce less vibration, making them perfect for many applications, including those who require accuracy and low noise.

The innovation behind 12V Brushless Motors is fascinating, along with the small 12v motor created by LEISON. They use an electronic controller manage engine's speed and gratification, helping to make them a lot more precise and responsive. This innovation also enables 12V Brushless Motors to work at variable rates while keeping efficiency, providing them with a definite benefit conventional motors that run at a fixed speed.

The sensors employed in these motors provide accurate feedback, enabling the motor to adjust to alterations in load, heat changes, along with other factors. This innovation is a must in making a versatile motor, dependable, and high-performing.

Safety is unquestionably an extremely element important of motor, even though the 12V Brushless Motor is no exclusion. One significant safety could be the motor's capability to turn fully off if you have a problem. The detect controller electronic such as overheating or overloading and will shut the motor right down to avoid further damage or dangers.

Additionally, 12V Brushless Motors are created to produce less electromagnetic interference which can restrict other electronic devices and cause dilemmas, same with LEISON's 12v-dc-motor-high-torque. The low electromagnetic interference them safer to use so much more circumstances, including painful and sensitive medical or scientific settings.

Having a 12V Brushless Motor is easy once you know how. Before using the engine, be sure that you have all the important equipment such as connectors and energy sources, in order to avoid any delays during procedure.

When you have all of the equipment, link the engine to your charged power source plus the load, also the micro gear motors manufactured by LEISON. It is very important so that the load is at the engine's abilities to avoid use or tear and harm. Then, turn the motor on Utilizing the controller, and it'll automatically adapt to the specified speed and performance.

Additionally it is important to frequently check out of the engine for any damage or deterioration and perform any essential maintenance keep it operating optimally.

The overall quality of 12V Brushless Motor is essential to it is longevity and performance. Reputable brands ensure that the engines undergo rigorous evaluation and inspection before launch towards the market. This testing assures buyers that the engine is of high quality and will perform needless to say.

The applications for 12V Brushless Motors are vast, as well as the LEISON's spur gear motors. They truly are well suited for robotics, electric cars, and drones, not limited by these applications only. They could additionally be found in medical and medical gear power, and many other industrial applications.