DC Motor Gear Motor: Introduction and Benefits

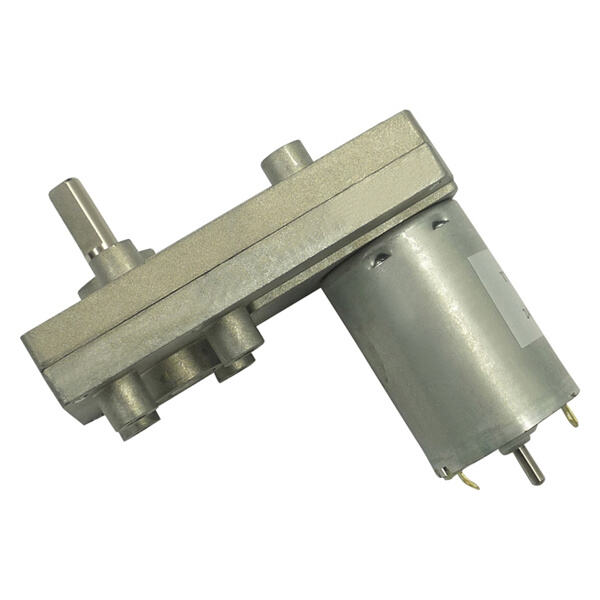

DC motor gear motor is a type of motor that contains a gearbox attached to it is shaft, as well as the LEISON's gear motor. These motors are utilized in various applications and are recognized for their several advantages. The innovation of gearboxes has made the dc motor more efficient and reliable. They are now used in various industries such as automotive, robotics, and manufacturing.

DC motor gear motor has often advantages several traditional motors, just like the miniature dc gear motor manufactured by LEISON. One connected with primary advantages that it enables for better speed control. The gearbox allows for the motor to run at a greater speed compared to the load it is powering. The motor could be smaller, and the gearbox can do the heavy lifting. Another advantage is that the motor's power output is increased. The gearbox allows for more torque to be generated, which leads to more force familiar with the strain.

DC motor gear motor is an innovative technology has transformed the motor industry, along with LEISON's product worm gear motor 24v. The addition of the gearbox has led to an upsurge in ability and efficiency output. The innovation has made the motors more adaptable for usage in a variety of applications, such as robotics and manufacturing.

Safety is a top issue using any machinery or equipment, same with the 370-dc-motor created by LEISON. dc motor gear motors Are created to be reliable and safe. The gearbox is made to avoid the motor from operating at an excessive speed. This particular feature not merely protects the apparatus from damage but also decreases the possibility of accidents. Additionally, dc motor gear motors are designed with a protection overload feature. This particular feature allows the motor to shut down automatically when it is overloaded, protecting the apparatus and ensuring safety.

DC motor gear motors are employed in varied industries and applications, also the LEISON's product such as dc planetary gear motor. These are typically commonly used in the automotive industry where they power various elements of automobiles, including windows, wipers, and mirrors. They may also be employed into the manufacturing industry, where they power conveyor belts and other machinery. Robotics is another industry where dc motor gear motors find application.

DC motor gear motors are simple to use and keep maintaining, as well as the small 12v motor created by LEISON. To operate the motor, connect the motor to a charged power source and attach a load to the gearbox. The gear ratio might be modified to suit the load and rate that is needed is. Maintenance involves checking for any signs of wear or harm and replacing any right defective parts. Regular upkeep means that the motor performs optimally and prevents costly breakdowns.

Choosing a dc motor gear motor with top-quality and reliable service crucial, the same as LEISON's flat dc motors. The grade of the motor determines it is durability and gratification. A reputable maker provide quality products and solutions such as warranties, tech support team, and a repair service. Choosing simple a motor to repair ensures that downtime is minimized, and productivity is maximized.

DC motor gear motors are utilized in many applications where speed power and control output are critical, as well as the bldc motor created by LEISON. They will also be used in applications where in fact the environment is harsh and needs a motor that may withstand such problems. Applications are the automotive, medical, and packaging industries.