The hybrid stepper motors are special motors that are being used in so many devices to help in the movement of such devices in a precise manner. They are important for automation and for robotics — for using machines to do jobs that people typically do. In this article, we'll take a closer look at how hybrid stepper motors work and why they are essential for getting things to move.

Hybrid stepper motors rely on the power of magnets as well as electric power to move. It’s this particular mix that makes these kinds of motors move so precisely—they can stop and start right on the money. This can work wonders for performing a task that requires precision, such as picking up a small item by guiding a robotic arm, or moving objects along a conveyor belt in a factory.

Automation and robotics are all about employing machines to perform tasks that might be difficult or dangerous for people. Hybrid stepper motors are ideal for these tasks, as their ability for accurate, consistent movement is a perfect fit. That’s because machines with these motors can move fast and are precise, making everything more efficient and errors less frequent.

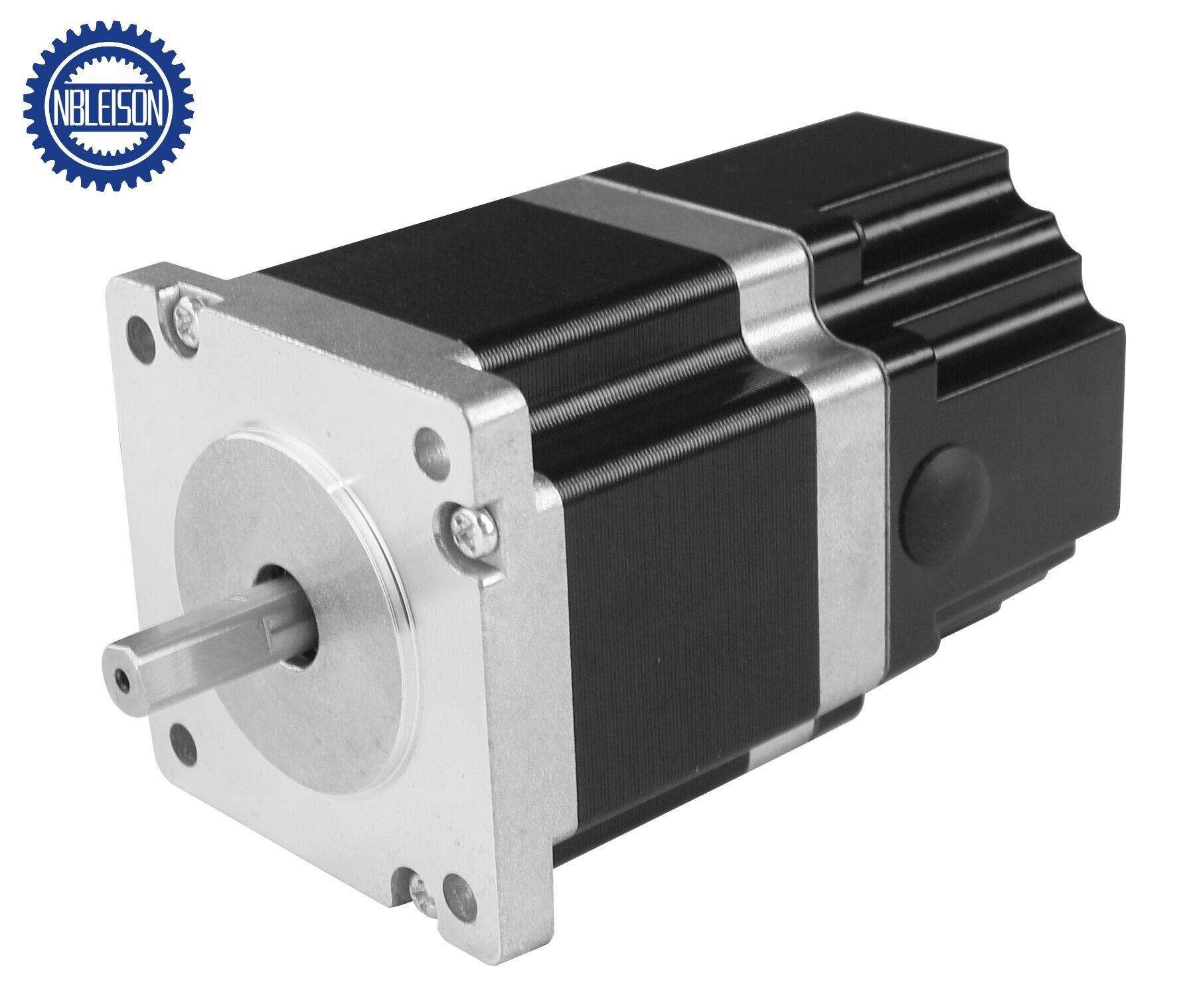

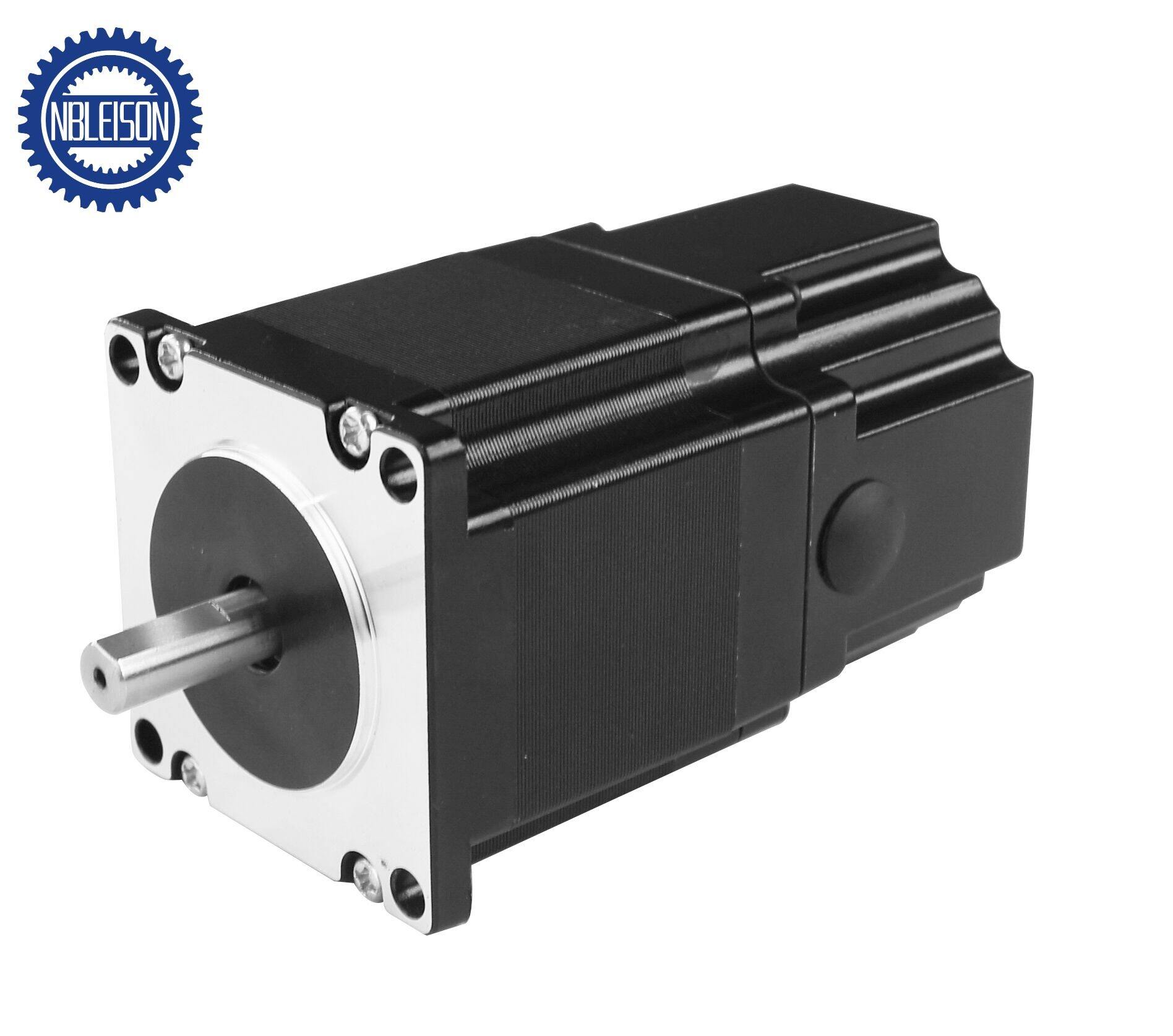

Hybrid stepping motors operate using two different types of magnets: permanent magnets and electromagnets. The permanent magnets are fixed in place, while the electromagnets can be switched on and off using electricity. If you adjust how much electricity goes to the electromagnets, the motor can turn in a really precise manner. This technology allows machines to move cleanly and in control.

In production environments that require speed and accuracy, hybrids are a good option. Quick and accurate, these motors are ideal for purposes like transporting products on a production line or steering a robotic arm. Using LEISON hybrid stepping motors, the drones are able to function faster and with improved precision, leading to higher productivity and reduced downtime for factory equipment.