42-stepper-motor are (I think) super cool, because they help machines move in a special way. They find applications in things like robots, 3D printers and some toys. In this article we are going to take a close look at stepper motors, what they are, how they work, why they are useful, and how to use and control them, along with issues such as resonance, and how to deal with them.

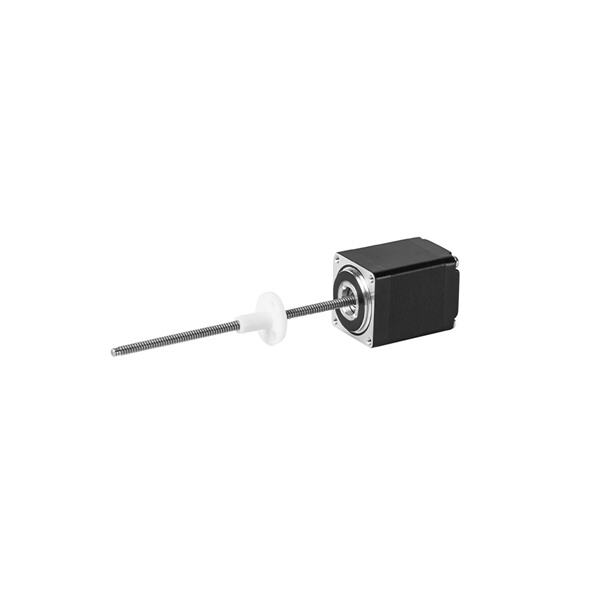

Stepper motors are unique because they move in small steps instead of continuously turning like other motors do. This, for example, helps them perform minute movements inside machines. They have coils, a rotor and a shaft, and together they all help things move just the way we need them to.

One of the great strengths of stepper motors is that they are capable of high positional precision. That way, they can go to a particular location as that location, rather than trying to guess. They also don’t have to have a sensor to tell where they are, so they’re simpler to control. Another advantage is that they can hold their position using little energy, so the saved power can be useful.

Hybrid-stepper-motors operate by alternatively switching on and off coils in a specific sequence. This results in magnetic forces that attract the rotor and cause it to rotate. By determining when and how to switch on each coil, we can cause the motor to move in various directions and at various speeds. I've seen these stepper motors so many times in machines (CNC machines, telescopes, some medical devices etc.)

Different types of stepper motors, and each moves in its unique way. The most popular varieties are permanent magnet, hybrid and variable reluctance stepper motor. Permanent magnet stepper motors have a magnet mounted in the rotor. Hybrid stepper motors are a mix between the other two designs and have permanent magnets and electromagnets within, and variable reluctance stepper motors contain teeth on the rotor and stator to ensure they move.

Occasionally a stepper motor problem rears its ugly head that you need to fix. One of the issues you might encounter is when the motor does not move either smoothly or makes a weird sound. This might be due to a poor connection, a coil is dirty, or the bearing is old. To repair this problem, you can clean the motor, tighten the loose components, or change the bearing if necessary.