Micro stepper motors are compact, but powerful units and are suitable for a variety of applications. They have come in handy in fields including robotics, electronics and manufacturing. In this guide we will cover the fundamentals of micro stepping motors, we will look at the advantages, the application and how to select the right micro-stepper for a project, and what to do if things go wrong.

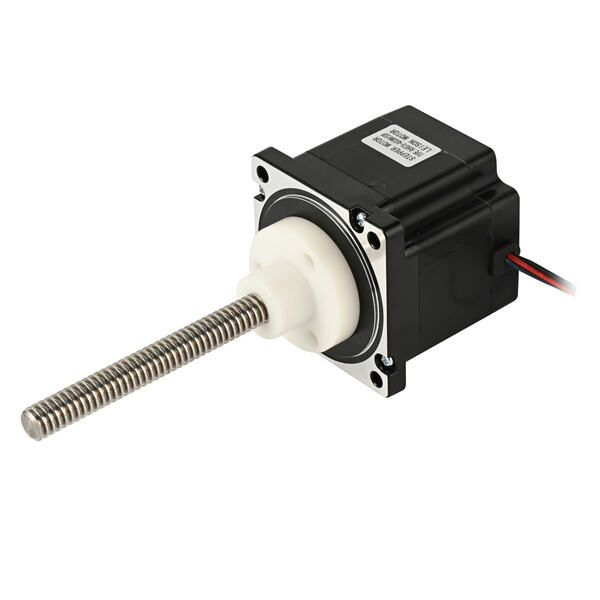

Micro stepper motors are a type of electric motor that moves with a small, precise amount of step. They’re perfect for applications that require precise movement, such as 3D printers, CNC machines and robots. These motors do their job by receiving electrical signals from a controller that dictates how far they should move.

There's a lot to like about micro stepper motors. For one, they are small and lightweight, and easy to cram into tiny devices. The second reason is better control over movement, so you can place things exactly where you want them in a more flowing motion. It’s flying high in satisfied customer reviews for a few reasons: First, it’s easy to install and sets up in under 30 seconds and, second, it’s quieter than many of the other motors we tried. Finally, they are relatively inexpensive which makes them a common choice for a lot of projects.

12v-micro-motors can be applied in dozens of different fields. In robotics, they assist in the operation of robotic arms and grippers with great precision. In electronics, they appear in disk drives and printers to achieve precise positioning. In industry, these robots are employed in computer-controlled machines that cut, shape, and drill materials very accurately (Computer Numerical Control machines).

Consider a few important things when choosing a micro stepper motor for your application. First, determine how much torque you require to make sure the motor is able to hoist or move the load. Then, have a look at the dimensions and the weight of the motor to determine if it fits in your device or not. Now think about how accurate you want your motor to be to pick the right step angle. Finally, you should also ensure the voltage and current rating matches your power supply.

Micro stepper motors will be in the same way like just about anything, that damage can occur. Some things that can go wrong are; overheating, losing steps, and making noise. If these problems are occurring, first examine the wires to ensure everything is connected properly. Then, check to ensure that the motor is receiving the correct voltage and current. If the temperature gets too high, you might need to add a fan or lower the load. If lose steps or you hear noise, you may try to increase the current parameter of the motors.